1 / 3

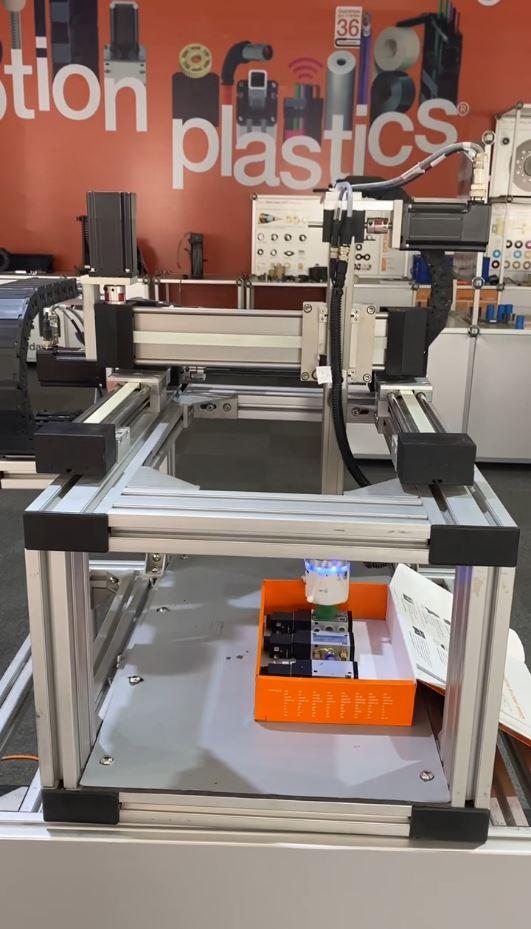

1 / 3Pick and place with small gantry robot

Hardware Price:

DOF

3

Nominal reach

400

mm

Working space

400x400x150

mm

Automating Manual Pick-and-Place with igus Gantry and Schmalz Cobot Pump

For industries working with pneumatic cylinders, solenoid valves, and accessories, automating repetitive tasks like pick-and-place is critical for improving productivity and efficiency. In this customer simulation, an igus gantry system equipped with a Schmalz Cobot pump replaces manual handling. The setup achieves up to 12 picks/min, with a repeat accuracy of 0.8 mm and a payload capacity of 2.5 kg on the gantry. The Cobot pump generates a vacuum of up to -600 bar, enabling secure handling of small parts up to 3 kg, making it ideal for precise automated processes.

What is the Application?

The system automates pick-and-place operations for pneumatic components in bin sorting or conveyor belt workflows, reducing manual effort and streamlining repetitive tasks.

What are the Advantages of the Solution?

High Precision: Reliable repeat accuracy of 0.8 mm ensures consistency.

Speed Optimization: Achieves up to 12 picks/min, boosting productivity.

Flexible Configuration: Supports camera systems, energy chains, and other accessories.

What are the Advantages of the Robot?

The igus gantry and Schmalz Cobot pump excel in automated handling:

Secure Gripping: Vacuum system ensures safe transport of small parts.

Versatile Design: Adaptable to various industries with customizable setups.

Durable Components: Built for long-lasting performance in demanding environments.

Precision and Efficiency with igus Gantry Solutions

By automating manual pick-and-place tasks, the igus gantry system with Schmalz Cobot pump enhances efficiency and accuracy in industrial workflows. With flexible integration options and reliable performance, this solution is ideal for modernizing processes while achieving cost-effective automation.

2 Components